Advertisement Feature – We have received payment for the contents of this article. Learn more.

The Audi A3 8P and Kawasaki Ninja ZX-6R represent two entirely different approaches to braking technology, each designed for their specific operating environments.

The Audi employs a comprehensive four-wheel braking system with ABS (anti-lock braking system), EBD (electronic brake-force distribution), and Emergency Brake Assist, creating a safety-focused setup that prioritises stability and predictable stopping power in everyday driving conditions.

Enjoy more The Classic MotorCycle Magazine reading every month.

Click here to subscribe & save.

In contrast, the Ninja ZX-6R utilises the advanced KIBS (Kawasaki intelligent anti-lock brake system) with cornering ABS capabilities, designed specifically for high-performance riding where precise control and instant response are crucial for safety.

The fundamental difference lies in how these systems manage braking force and rider interaction. The Audi’s systems work together to ensure maximum stability, automatically distributing braking force between wheels and providing emergency assistance when rapid deceleration is detected. The Kawasaki’s KIBS system, however, monitors multiple parameters including throttle position, engine speed and lean angle to provide sophisticated braking control that adapts to the dynamic nature of motorcycle riding, particularly during cornering where traditional ABS systems might prove inadequate.

Understanding brake system components

Both vehicles rely on disc brake technology as their foundation. According to Onlinecarparts: “Brake disc is connected to the wheel hub. When braking brake blocks press themselves to the brake disc. Because of friction the speed goes down. As a rule, brake discs are made only of a high-quality metal. They are harder than brake blocks that is why there is no necessity often to replace them. In modern sports cars instead of metal carbonado or composite ceramics is used. This kind of brakes is more effective. The following effectiveness increase is possible due to usage of ventilation ducts in brake discs. While brake disc substitution, brake blocks are also subject to substitution.”

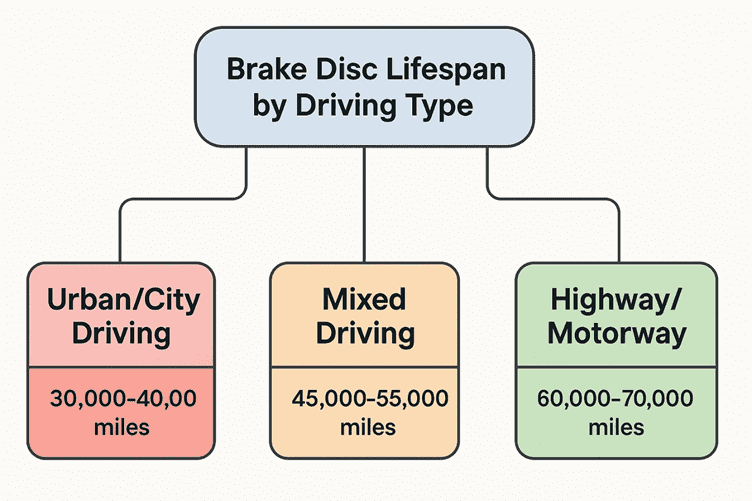

Statistical data shows that brake discs typically last between 30,000 to 70,000 miles under normal driving conditions, with an average replacement interval of around 50,000 miles. However, this varies significantly between the two vehicles due to their different operating conditions and usage patterns.

The diagram illustrates how driving conditions dramatically affect brake disc longevity. Urban driving with frequent stop-start traffic reduces disc life to just 30,000-40,000 miles, while motorway driving can extend this to 70,000 miles. Performance driving, typical of the Ninja ZX-6R’s use, places the highest demands on braking components, often requiring replacement every 20,000-35,000 miles.

Audi A3 8P safety through stability

The Audi A3 8P’s braking system prioritises passenger safety through predictable, stable performance. The ABS prevents wheel lock-up during hard braking, while the EBD system automatically adjusts braking pressure to each wheel based on load distribution and road conditions. The Emergency brake assist system detects panic braking situations by monitoring brake pedal application speed and force, automatically applying maximum braking pressure when needed.

This integrated approach works particularly well in urban driving and motorway conditions, where the vehicle’s weight and electronic systems combine to provide reassuring stopping power. The system’s design accounts for variable passenger loads and weather conditions, ensuring consistent performance regardless of circumstances.

Kawasaki Ninja ZX-6R performance through precision

The Kawasaki’s KIBS represents a more sophisticated approach to motorcycle braking. Unlike standard ABS systems, KIBS links the ABS electronic control unit directly with the engine management system, monitoring front brake calliper hydraulic pressure, throttle position, engine speed, clutch operation, and gear selection. This comprehensive data analysis enables the system to modulate brake pressure in much finer increments than conventional systems.

The front brake of the motorbike is the main brake of the machine, typically providing 70-80% of total stopping power. KIBS takes this into account, managing rear wheel lift during heavy braking while maintaining the natural feel that experienced riders expect. The system’s cornering ABS capability represents a significant advancement, using lean angle sensors to adjust braking intervention based on the bike’s position in a turn.

Different conditions require different solutions

| Feature | Audi A3 8P | Kawasaki Ninja ZX-6R |

| Brake System Type | Four-wheel disc with ABS/EBD | KIBS with cornering ABS |

| Primary Safety Focus | Stability and predictability | Performance and precision |

| Brake Force Distribution | 60% front / 40% rear | 70-80% front / 20-30% rear |

| ABS Response Time | Standard (10-15 cycles/second) | High-precision (up to 25 cycles/second) |

| Electronic Integration | Basic ABS/EBD coordination | Full engine-brake system link |

| Cornering Capability | Limited lean-angle compensation | Advanced cornering ABS with IMU |

| Service Interval | 45,000-60,000 miles | 25,000-40,000 miles |

| Emergency Brake Assist | Yes (automatic activation) | Manual rider control priority |

The technical comparison reveals significant differences in how these vehicles approach braking challenges. The Audi A3 8P distributes braking force with a 60% front and 40% rear split, optimising for four-wheel stability. In contrast, the Ninja ZX-6R relies heavily on front brake dominance with 70-80% of stopping power coming from the front wheel, requiring more sophisticated control systems to manage this concentrated braking force safely.

The ABS response times differ markedly, with the Kawasaki’s KIBS system operating at up to 25 cycles per second compared to the Audi’s standard 10-15 cycles per second. This higher frequency allows for finer brake pressure modulation essential for motorcycle dynamics. Service intervals also reflect usage intensity, with the performance-oriented motorcycle requiring brake attention every 25,000-40,000 miles compared to the Audi’s 45,000-60,000 mile intervals.

The key distinction between these systems lies in their operational philosophy. The Audi system excels in providing consistent, stable braking performance for everyday driving, automatically compensating for driver input variations and road conditions. The vehicle’s substantial weight and four-wheel contact patch allow for more forgiving braking characteristics.

The Kawasaki system, conversely, must work within the constraints of two-wheel vehicle dynamics, where rider skill and precise control are essential. The system provides safety intervention whilst preserving the direct connection between rider input and machine response that motorcyclists depend on for both safety and performance.

AUTODOC, a leading authority in automotive brake technology, emphasises that both systems represent optimal solutions for their respective applications, demonstrating how modern braking technology adapts to meet the specific demands of different vehicle types and operating conditions.

Understanding these differences helps explain why a car and motorcycle approach the same fundamental task – stopping safely – through such different technological solutions.